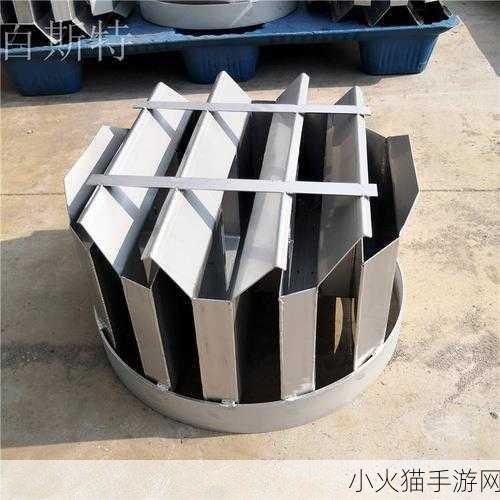

液体收集器系统HH的基本概念

液体收集器系统HH是一种高度专业化的设备,广泛应用于工业、实验室以及医药等领域。该系统旨在高效、安全地收集和储存各种类型的液体,无论是危险化学品还是生物样本。这类设备通常具备自动监测、报警、防泄漏等功能,以确保操作过程中的安全与效率。

主要功能与优势

液体收集器系统HH配备多种先进技术,使其能够满足不同用户需求。例如,其智能监控模块可以实时跟踪流量变化,并提供数据分析服务。此外,多重过滤机制有效减少了对环境的潜在污染风险,尤其适用于涉及有害物质或敏感试剂的场合。

并且,该系统具有良好的兼容性,可以接入现有生产线,与其他设备无缝连接。这对于寻求提升生产效率及降低人工成本的企业来说,是一个不可忽视的重要因素。同时,经过严格测试后推出的新型材料,不仅提高了耐腐蚀性,还延长了使用寿命,从而为企业节约了一定运营费用。

设计考虑与用户体验

User-friendly design is a key element in the HH system. The intuitive interface allows operators to easily navigate through various functions, minimizing training time and reducing human error risks. Additionally, customizable settings enable users to tailor the device according to their specific requirements, further enhancing operational efficiency.

The compact design of the liquid collector saves valuable space without compromising on performance. This attribute is particularly beneficial for laboratories or industrial facilities with limited room for additional equipment. Furthermore, noise reduction technology ensures that operations maintain a low decibel level, contributing to a more pleasant working environment.

安全措施及标准遵循

Safety remains at the forefront of any liquid handling operation. Liquid collector systems like HH are designed following stringent industry standards such as ISO 9001 and CE certification. These certifications guarantee that devices meet high-quality benchmarks while ensuring compliance with local regulations concerning hazardous materials.

The inclusion of emergency shut-off features provides an added layer of protection against accidents caused by spills or leaks. Users can set up automatic alerts via SMS or email notifications when parameters exceed preset limits—this proactive approach significantly mitigates potential hazards associated with fluid management.

维护与保养建议

A regular maintenance schedule should be established to ensure optimal functioning of the HH system over its lifespan. Routine checks include inspecting seals and gaskets for wear-and-tear signs and cleaning filters as needed based on usage frequency.

Lubrication points must also be monitored regularly so machinery operates seamlessly during collection cycles; neglecting this aspect could lead not only breakdowns but also costly downtime impacts overall production capabilities!

"Effective monitoring strategies play crucial role improving output quality!" - Research Analyst "Liquid Collection Technologies: An Overview"