TPU色母与子色母的基础知识

热塑性聚氨酯(TPU)是一种兼具弹性和强度的材料,广泛应用于各类产品中,如鞋底、手机保护壳及汽车内饰等。为了实现不同颜色和功能需求,加入色母是制造过程中不可或缺的一部分。根据配方设计,可以将颜料均匀地分散在基材中,从而达到理想的外观效果。

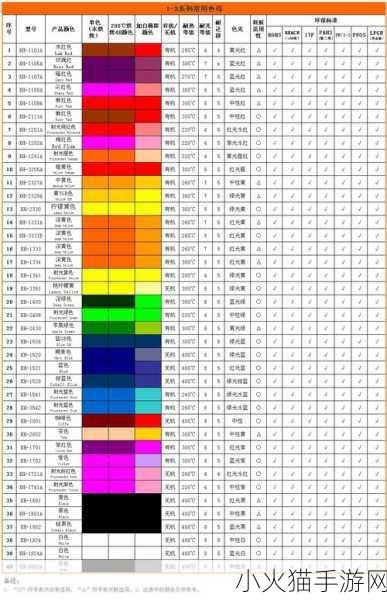

色母通常可以分为两大类:主流使用的“色粉”以及特殊性能增强型的“子色母”。它们不仅影响最终产品的美观,还对物理性质如耐磨损、耐UV等有显著作用。这些因素直接关系到产品质量和市场竞争力,因此了解二者间差异至关重要。

TPU中色母的特性分析

常规 TPU 色母主要用于赋予材料丰富多彩的视觉体验,其优点包括高着色力、良好的光稳定性及适应各种工艺条件。在生产过程中,这种类型的颜色添加剂能够保持高度一致性的颜色表现,同时不干扰基本树脂性能。此外,它们具有较低挥发性的特点,有助于减少成品中的气味问题,提高用户体验。

CNC加工或者注射成型技术一般采用这种方法进行处理,使其更易满足现代工业化生产需要。同时,由於 TPU 的独特结构,附加上合适比例的小颗粒染料,可以在很大程度上提升制品表面光泽度,让整体效果更加精致。而且,高浓缩能力使得少量添加即可获得鲜艳持久的人造效果,为企业降低了成本负担。

子色母的重要作用

相较于传统色粉,子色母往往包含一些额外功能,比如抗紫外线、阻燃、防静电等。因此,在许多高要求场景下,例如电子设备和户外用品,对其使用频率逐渐增加。由于这些功能层次更复杂,相应研发投入也随之增大,但所带来的品质提升则足以弥补投资成本。

A good example is the use of UV-stabilized color masterbatches, which ensure that outdoor products maintain their vibrant colors over time despite sun exposure. This could be particularly useful in applications like automotive parts or construction materials.

选择合适类型的重要考量

Selecting between color masterbatch and functional additive masterbatch depends largely on end-use requirements. For instance, if a product requires not only aesthetic appeal but also additional properties such as heat resistance or enhanced durability, then integrating both types may yield optimal results.

The compatibility with different processing techniques should also be evaluated during selection. Some applications might favor traditional coloring methods due to cost-effectiveness while others benefit from advanced functional additives for specialized needs.

TOTF (total optimized treatment factors)

This concept emphasizes balancing aesthetics and functionality when choosing between various types of TPUs and their respective color schemes. The key lies in understanding how these choices impact performance characteristics throughout the lifecycle of the product—from manufacturing through usage—and even into disposal stages where recyclability becomes crucial.